The Open Flame Rock n Roll Rotomolding Machine fabricated by us is quite popular in the market for its competitive price and robust construction. These machines are most suitable to develop large size hollow products of up to 40,000 ltr./ 10,000 mg capacity. There are AC motors with speed variable drive for rolling and rocking actions to control the speed through a panel board. It further results in smooth rubbing without any jerks. Outside individual adjustable burners are user friendly and are easy to use by operators who have little technical knowledge. Also, these burners ensure effective burning; trouble-free operation for a longer time and fuel is consumed at a lower rate. There is a cooling station with a rolling drive ascertaining optimum efficiency and has a sturdy steel structure. We are leading Manufacturer, Supplier and Exporter of Open Flame Rotomolding Machine in Ahmedabad, India.

In addition, some additional accessories like Pneumatic Second Charging Unit (Pneumatically Operated) can be availed by the customer on request. To satisfy our valuable clients, we also provide a sampling facility for our machines. Further, the Open Flame Rock n Roll Rotomolding Machine is widely used for manufacturing large size cylindrical vertical containers, and allied products. Further, it finds application in the roto lining of products. While designing the machinery, it is very crucial to maintain the highest engineering standards as well as international quality norms. Highly experienced engineers and technocrats design Open Flame Rock n Roll Machine to match up the expectations of national as well as global buyers. Consistent market researches, employment of new technologies, and improvising product design help in making the Open Flame Rock n Roll Rotomolding Machine catering to stimulating market demands.

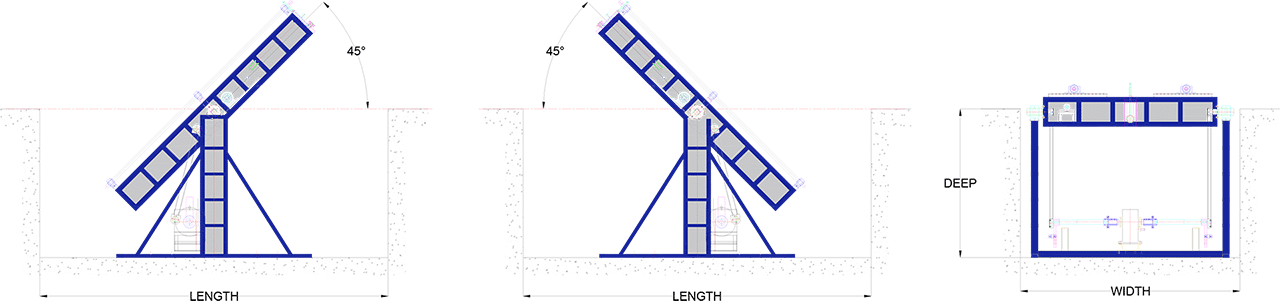

Features of Open Flame Rotomolding Machine

- Widely accepted and common way of operation which is user friendly and easy

- Faster return on investments and low production cost

- Various models flexible in producing vertical tanks from 200 ltr to 25000 Ltr

- Low-pressure burners are easily adjustable from the outside. These have a simple design and ascertain faster heating.

- Minimal chance of product rejection, as the whole process is visible

- Less maintenance