Three Arm Biaxial Machine Manufacturer

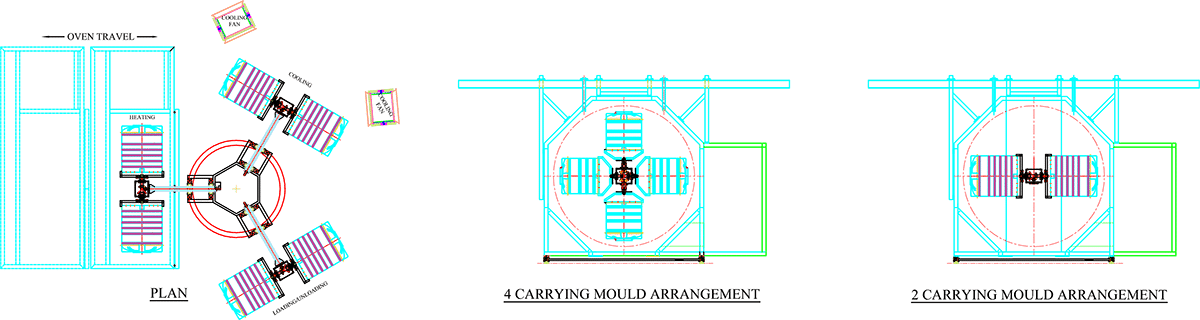

Three Arm rotomolding machine is named because it’s three-station machines with a fixed turret and oven. The machine is very demanding because of its myriad usage and high volume production. It has also another advantage is that the cost of production is less than other molding machines. Three Arm rotomolding machine has three independent turntables with a central axis and independent rotation. The three stations work independently and do not affect the location and processing of other arms. The independence of arms creates a flexible approach and eventually more production. We manufacture and supply a world-class range of Three arm rotational molding machine, also give the customization facility so that clients can custom build their products according to their need.

Our three-arm rotational molding machines are used to produce different types of plastic products. This also includes technology domains such as the aircraft industry and large section industries. The machine is best suited to mould one-piece hollow parts or double-wall open containers. There is another part of this machine, which is used to cut out panel to manufacture single-wall open containers and products. The machine helps to minimize wastage, allowing smooth cutting/trimming operation. Most of the time we use polyethene, though some internal “kiss-off” can be better utilized between the double walls of the hollow part.

Features of Three Arm Rotomolding Machines

- The fastest machine in the rotomolding section

- Great flexibility and adaptability to produce a large volume in the shortest period

- Fast cooking and heating times

- Big articles up to 6.4 m can easily be produced